The role and effect of silicone oil in the field of machinery

Silicone oil, as a multifunctional grease composed of silicon and mineral oil, plays a crucial role in the mechanical field due to its excellent physical and chemical properties. This article will explore in detail the application and effects of silicone oil in the mechanical field from three aspects: lubrication, heat dissipation, and insulation performance.

1、 The lubricating effect of silicone oil

Silicone oil has excellent lubricating properties and is an indispensable lubricant in the mechanical field. The long-chain alkyl groups and silicon oxygen bonds in its molecular structure enable silicone oil to form a thin and tough lubricating film between two friction surfaces. This film can effectively reduce friction and wear between mechanical components, thereby reducing heat dissipation and equipment loss.

In high-precision and high load equipment such as textile machinery and automotive engines, the lubricating effect of silicone oil is particularly prominent. During the operation of textile machinery, friction between various components generates a large amount of heat and wear, and the use of silicone oil can significantly reduce this friction and wear, extending the service life of the equipment. Similarly, in automotive engines, silicone oil can ensure smooth operation between various components, reduce heat and wear caused by friction, and improve engine power and efficiency.

In addition, silicone oil also has excellent antioxidant properties and can maintain stable lubrication effects in harsh environments such as high temperature and high pressure. This has made silicone oil widely used in mechanical equipment that requires long-term and high-intensity operation.

2、 The heat dissipation effect of silicone oil

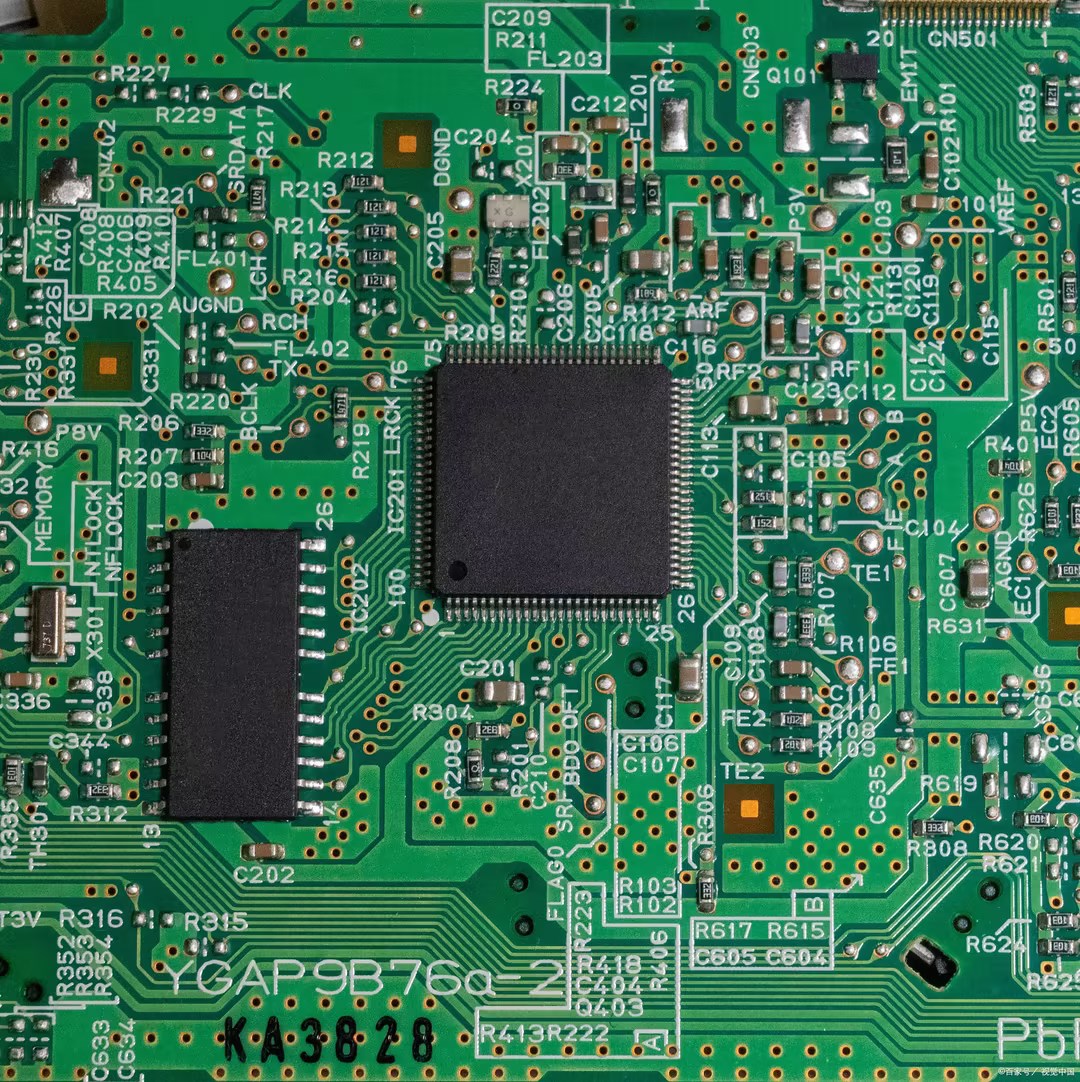

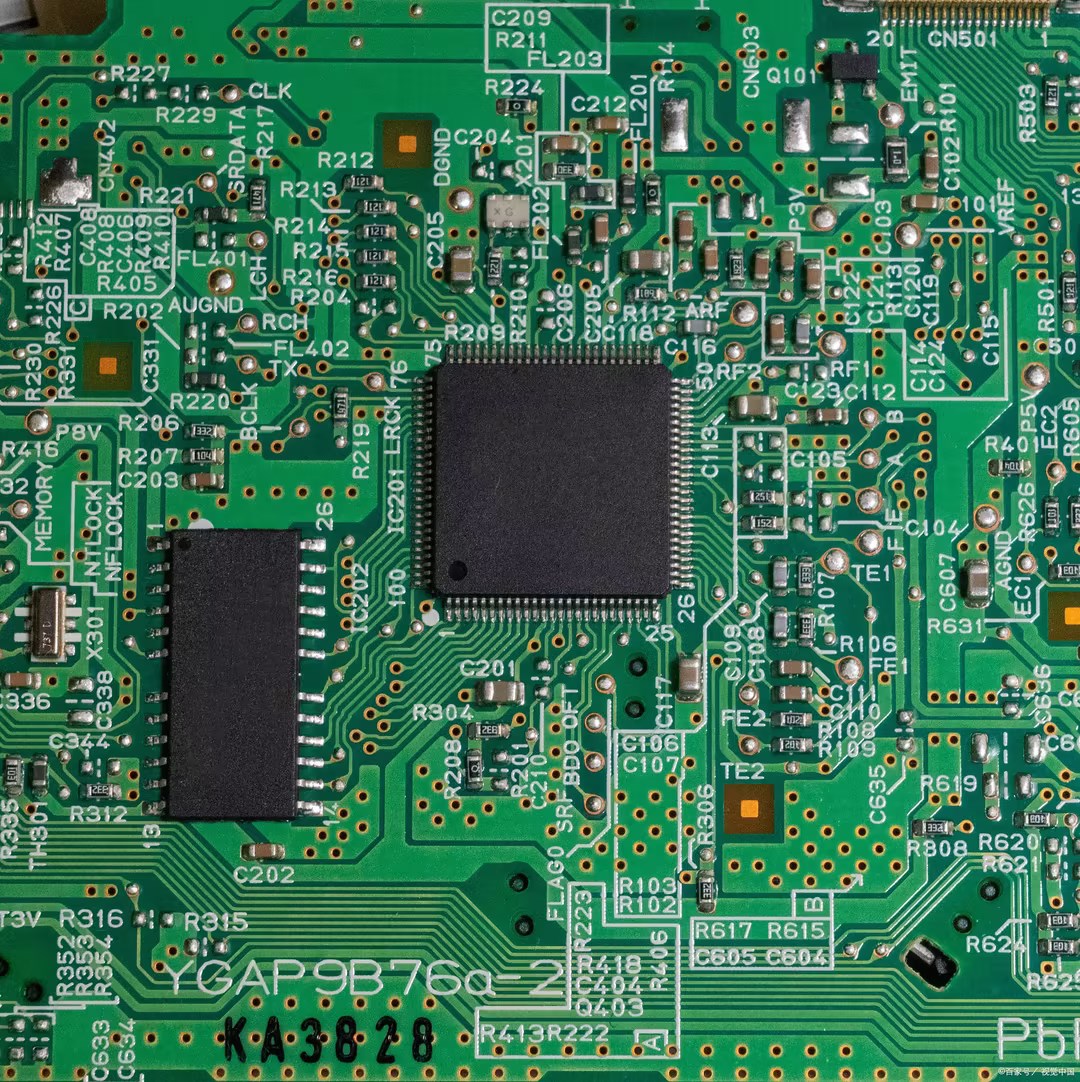

In addition to its lubricating effect, silicone oil also has excellent heat dissipation performance. Silicone oil plays a crucial role in the heat dissipation of electronic devices such as computer CPUs and large industrial electrical equipment. As a component of heat dissipation paste, silicone oil can fill gaps, promote rapid heat conduction, and prevent equipment from overheating.

With the development of technology, the power of modern electronic devices is increasing, and the problem of heat dissipation is becoming more prominent. Traditional heat dissipation methods such as fans and heat sinks are no longer able to meet the heat dissipation needs of modern electronic devices. As an efficient heat dissipation material, silicone oil can significantly improve the heat dissipation efficiency of electronic devices, reduce their temperature, and thus extend their service life.

In addition, silicone oil also has excellent insulation properties, which can ensure the electrical safety of electronic devices while ensuring heat dissipation. This has made silicone oil widely used in situations that require high heat dissipation performance and electrical safety.

3、 Insulation performance of silicone oil

The insulation performance of silicone oil is another important aspect of its application in the mechanical field. Due to its non-conductive nature and high electrical resistivity, silicone oil can be used as an insulation material for electrical equipment. Applying silicone oil to metal surfaces or forming coatings for application can effectively prevent electrical faults such as current leakage and short circuits.

In the manufacturing of wires and cables, silicone oil can form an insulating coating to ensure that the current is transmitted along the predetermined route. This not only improves the electrical safety of wires and cables, but also enables them to maintain stable performance in harsh environments. In addition, silicone oil can also be used for insulation components of some high-voltage electrical equipment, such as transformers, capacitors, etc. These devices need to withstand extremely high voltage and current during operation, and the insulation performance of silicone oil can effectively protect these devices from electrical faults.

4、 Other functions of silicone oil

In addition to the above three aspects, silicone oil also has various other functions in the field of machinery. For example, silicone oil can be used for cleaning and corrosion prevention. During the operation of mechanical equipment, a large amount of dirt and corrosive substances are generated, and silicone oil can effectively clean these dirt and prevent corrosion from occurring. In addition, silicone oil can also be used to eliminate static electricity between mechanical components to prevent damage to electronic devices and electronic components. In the manufacturing of adhesives, silicone oil can also provide good UV resistance, acid and alkali resistance, waterproof performance and anti-aging performance.

5、 Precautions for using silicone oil

5、 Precautions for using silicone oil

Although silicone oil has a wide range of applications and significant effects in the mechanical field, the following points should still be noted during use:

Choose the appropriate silicone oil model: Different mechanical equipment and working environments have different requirements for silicone oil, so it is necessary to carefully select the appropriate silicone oil model before use.

Avoid pollution: Silicone oil should be avoided from contact with impurities such as dust and moisture during use to avoid affecting its lubrication and heat dissipation effects.

Regular replacement: Silicone oil will gradually age during use, so it needs to be replaced regularly to ensure its stable performance.

Attention to safety: Although silicone oil is non-conductive, electrical safety should still be taken into account during use to avoid accidents such as electric shock.

Recommend product:201 :https://www.112seo.com/product-my-201-methyl-silicone-oil-.html

In summary, silicone oil has a wide range of applications and significant effects in the field of machinery. Its excellent lubrication, heat dissipation, and insulation properties make silicone oil an indispensable lubricant in mechanical equipment. During use, it is important to choose the appropriate silicone oil model, avoid contamination, regularly replace it, and pay attention to safety issues. I believe that with the continuous advancement of technology and the continuous development of silicone oil technology, the application of silicone oil in the field of machinery will become more extensive and in-depth.