Polyether silicone oil and methyl silicone oil, as important branches of silicone materials, are widely used in industry and daily life. Although they differ in structure and performance, they also share many similarities that make them similar in certain application areas.

product link:

https://www.112seo.com/productcategory-polyether-silicones.html

1. Fundamentals of Chemical Structure

The basic skeleton of polyether silicone oil and methyl silicone oil is polydimethylsiloxane (PDMS), which endows them with many similar physical and chemical properties. Polydimethylsiloxane has excellent chemical stability, heat resistance, and low surface tension, which are reflected in both polyether silicone oil and methyl silicone oil.

2. Heat resistance and chemical stability

2. Heat resistance and chemical stability

Methyl silicone oil and polyether silicone oil both have excellent heat resistance and chemical stability. The heat resistance of methyl silicone oil can reach over 200 ℃, while the heat resistance of polyether silicone oil is also preserved after introducing polyether groups. In addition, their chemical inertness makes them exhibit good stability in various chemical environments and not easily react with other substances.

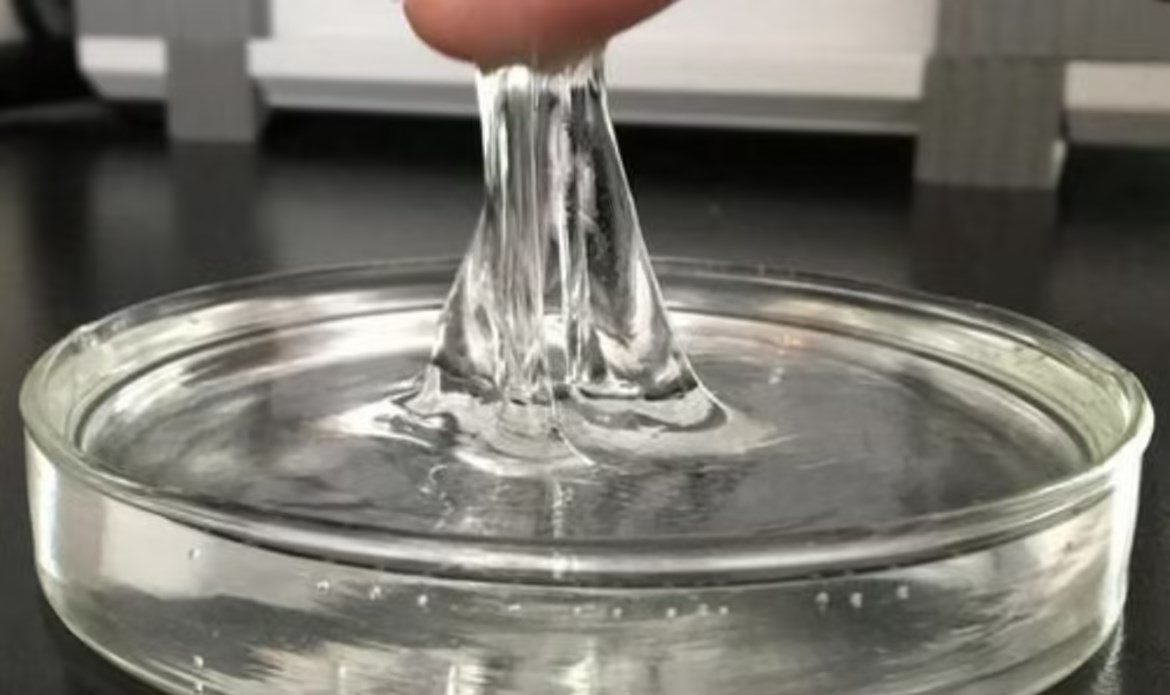

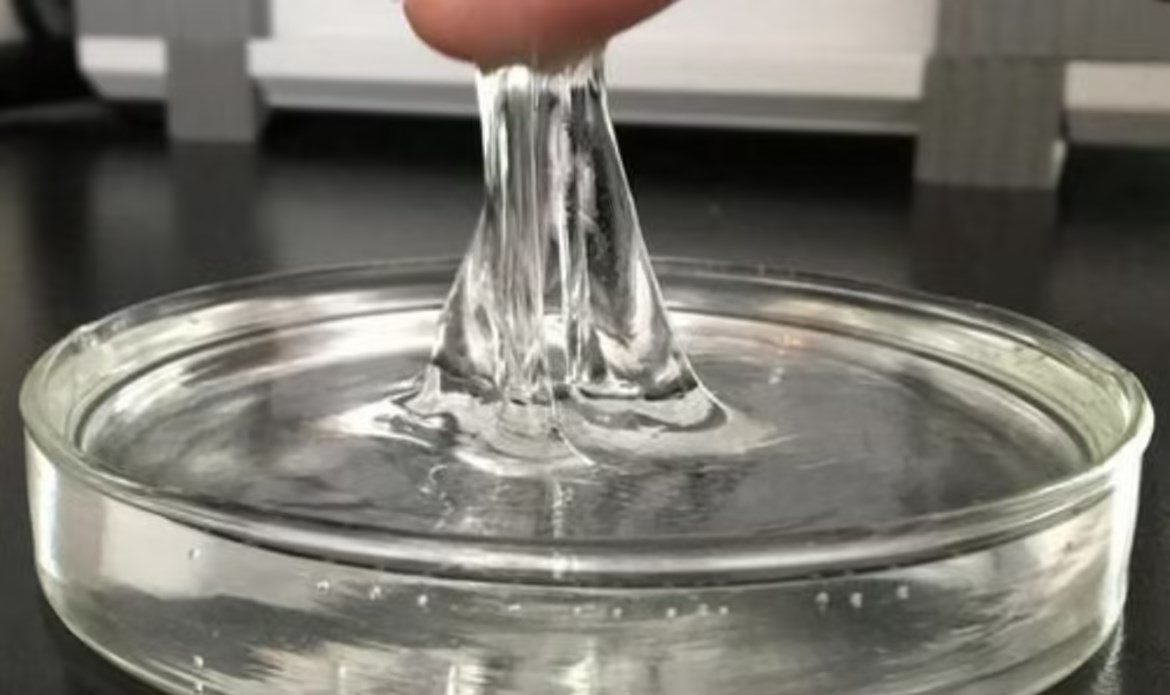

3. Low surface tension and lubricity

Polyether silicone oil and methyl silicone oil both have low surface tension and excellent lubricity. This characteristic makes them perform well in lubrication, shock resistance, dust prevention, and other fields. For example, methyl silicone oil is commonly used for mechanical lubrication and shock resistance in electronic devices, while polyether silicone oil provides softness and lubricity in textile finishing.

4. Wide range of application areas

4. Wide range of application areas

There is a certain overlap in the application fields of polyether silicone oil and methyl silicone oil. Methyl silicone oil is widely used in the fields of electronics, machinery, and chemical engineering due to its excellent heat resistance and chemical stability. Polyether silicone oil is commonly used in textile finishing, cosmetics, and shampoo products due to its hydrophilicity and softness. In addition, both can be used in coatings and plastic products as leveling agents or anti-static agents.

5. Safety and environmental friendliness

Polyether silicone oil and methyl silicone oil are both non-toxic, non corrosive materials, and environmentally friendly. This characteristic has made it widely used in industries such as food, medicine, and cosmetics.

6. Emulsification and dispersion characteristics

Polyether silicone oil and methyl silicone oil both have good emulsifying and dispersing properties. Polyether silicone oil enhances its dispersibility in water by introducing polyether groups. Methyl silicone oil is commonly used to prepare emulsions for lubrication and shock absorption.

summary

Although polyether silicone oil and methyl silicone oil have differences in structure and properties, they share many similarities in chemical stability, heat resistance, low surface tension, and lubricity. These commonalities enable them to exhibit similar characteristics in certain application fields and meet various industrial and daily needs.