The Diversified Role of Silicone Resin in Industrial Applications

1、 Introduction

With the rapid development of modern industry, the application scope of materials is constantly expanding. Silicone resin, as a high-performance organic silicon material, has played an indispensable role in many industrial fields. This article will focus on the application of silicone resin in different industrial fields and analyze its importance for industrial production.

https://www.112seo.com/productcategory-modified-phenyl-silicone-oils.html

2、 Application of Silicone Resin in the Electronic and Electrical Industry

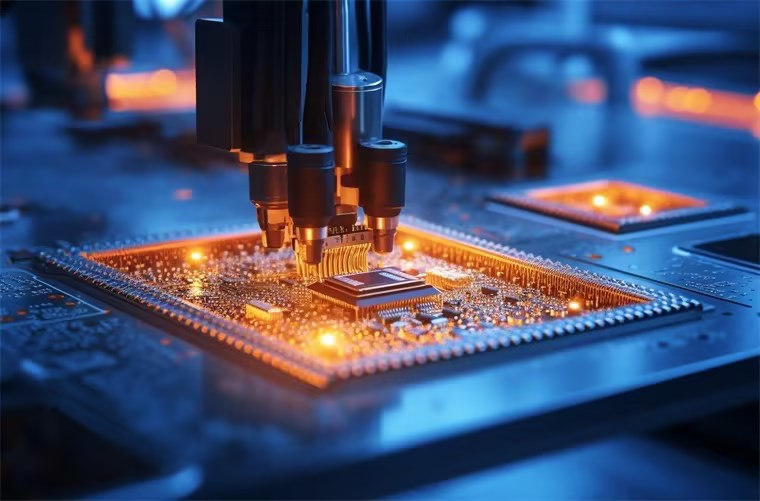

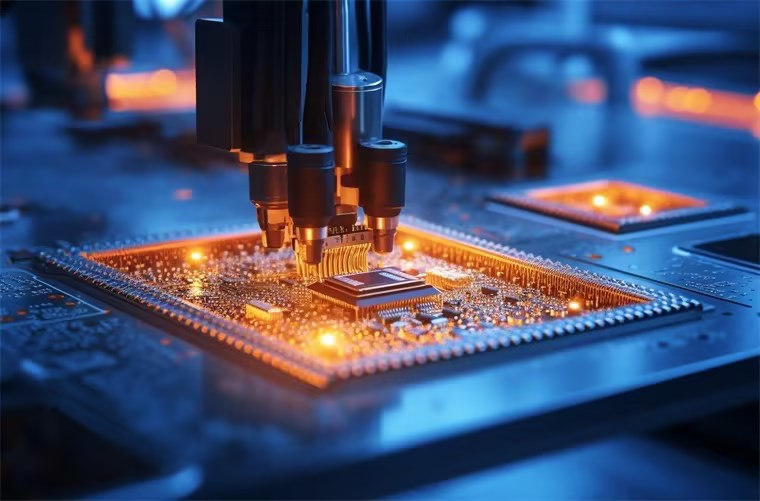

Electronic component packaging

In the electronics and electrical industry, silicone resin is widely used as a packaging material for electronic components. Electronic components are subject to various environmental factors such as humidity, high temperature, and mechanical vibration during use, and silicone resin encapsulation adhesive can provide reliable protection for electronic components. For example, in integrated circuit packaging, silicone encapsulation adhesive can effectively prevent the circuits inside the chip from being corroded by the external environment, thereby extending the service life of the chip.

Insulation material

Insulation material

The electrical insulation performance of silicone resin has made it widely used in electronic and electrical equipment. Silicone resin insulation paint is used to coat wires, cables, and transformer windings, which can effectively prevent the generation of arcs and corona, thereby ensuring the safe operation of equipment. In addition, silicone insulation tape is also commonly used for maintenance and insulation treatment of power equipment.

Electronic device heat dissipation

Silicone resin is also used as a heat dissipation material for electronic devices. By adding thermal conductive fillers (such as alumina, boron nitride, etc.) to silicone resin, high thermal conductivity silicone resin thermal conductive adhesive can be prepared. This thermal conductive adhesive can effectively dissipate the heat inside electronic devices, ensuring their normal operation.

3、 Application of Silicone Resin in Aerospace Field

Manufacturing of high-temperature components

The aerospace industry has extremely high requirements for material performance, and silicone resin has been widely used in this field due to its excellent temperature resistance and mechanical properties. For example, silicone based composite materials are used to manufacture high-temperature components for aircraft engines and insulation layers for spacecraft, which can effectively resist the erosion of extreme environments.

Sealing material

Sealing performance is crucial in aerospace equipment. Silicone sealant has good elasticity and high temperature resistance, which can effectively prevent fuel leakage and air leakage. For example, in the sealing of aircraft fuel systems, silicone sealant can withstand high temperature and high pressure environments, ensuring the safe operation of the fuel system.

Anticorrosive coating

Aerospace equipment is susceptible to corrosive gases and liquids during use. Silicone anti-corrosion coating can effectively protect the surface of equipment and prevent corrosion from occurring. For example, coating the surface of aircraft fuselage and engine components with silicone anti-corrosion coating can extend the service life of the equipment.

4

、 Application of Silicone Resin in the Construction Industry

Sealing glue and waterproof coating

In the field of construction, silicone resin is used to manufacture high-performance sealants and waterproof coatings. Silicone sealant has good elasticity and weather resistance, which can effectively prevent leakage and deformation of buildings. For example, in the installation of doors and windows and the treatment of building joints, silicone sealant can maintain its sealing performance for a long time. In addition, silicone waterproof coatings can provide long-term waterproof protection for buildings, while also having good breathability and UV resistance.

Building insulation materials

Silicone resin can also be used to manufacture building insulation materials. By compounding silicone resin with other insulation materials, high-performance insulation boards can be prepared. This type of insulation board has good thermal insulation and fire resistance properties, which can effectively reduce the energy consumption of buildings.

Decorative materials

Silicone resin is also widely used in building decoration materials. For example, silicone resin coatings can be used for the decoration of building exterior walls, with good weather resistance and stain resistance. In addition, silicone resin can also be used as a surface treatment agent for building decorative stone, which can effectively improve the durability and aesthetics of the stone.

5、 Application of Silicone Resin in the Automotive Industry

Sealing of engine components

5、 Application of Silicone Resin in the Automotive Industry

Sealing of engine components

In the automotive industry, silicone resin is used as a sealing material for engine components. The engine generates high temperature and pressure during operation, and silicone sealant can effectively prevent coolant and oil leakage. For example, in the sealing of engine cylinder block and cylinder head, silicone sealant can withstand high temperature and high pressure environments, ensuring the normal operation of the engine.

Protection of automotive electronic devices

With the continuous improvement of automotive electronicization, the protection of electronic devices has become increasingly important. Silicone resin encapsulation adhesive is used for packaging automotive electronic components, which can effectively prevent electronic components from being affected by moisture and high temperature. For example, in the packaging of automotive electronic control units (ECUs), silicone encapsulation adhesive can extend the service life of electronic components.

Auto Interior Material

Silicone resin can also be used for surface treatment of automotive interior materials. For example, silicone leather treatment agents can improve the wear resistance and stain resistance of car seat leather, while also providing a good touch and appearance.

6、 Conclusion

Silicone resin, as a high-performance organic silicon material, has been widely used in various industrial fields such as electronics and electrical, aerospace, construction, and automotive. Its excellent temperature resistance, electrical insulation, weather resistance, and chemical stability enable it to meet various demanding industrial needs. With the continuous development of industrial technology, the application scope of silicone resin will further expand, providing more reliable support for the development of modern industry.